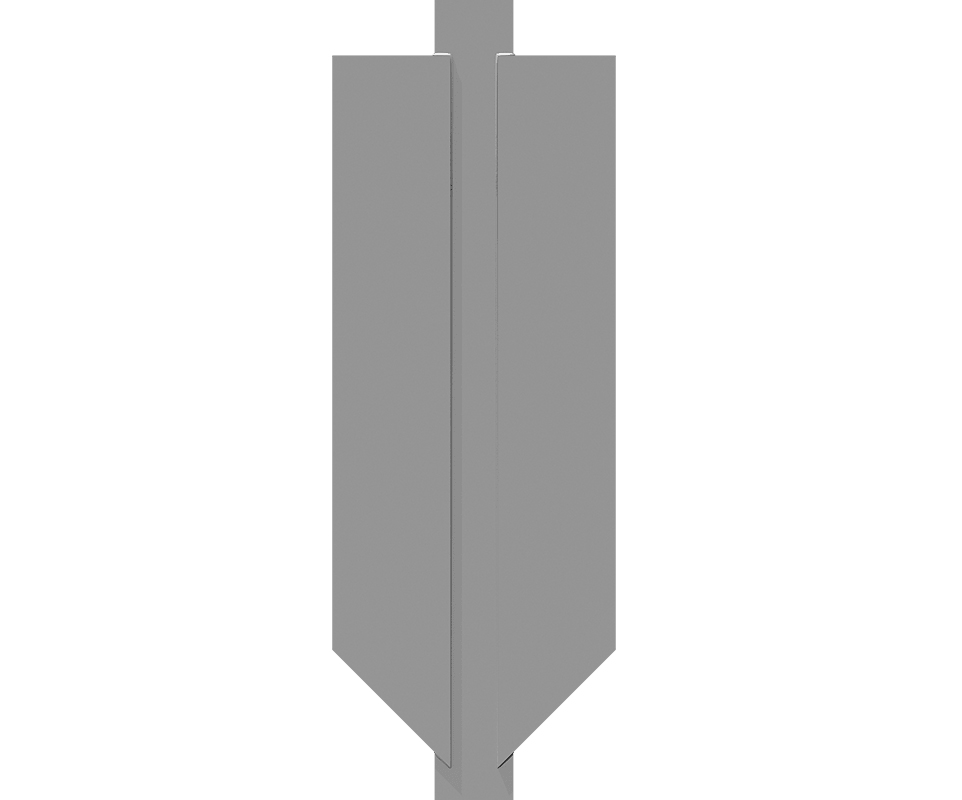

Solar X Blade Pile

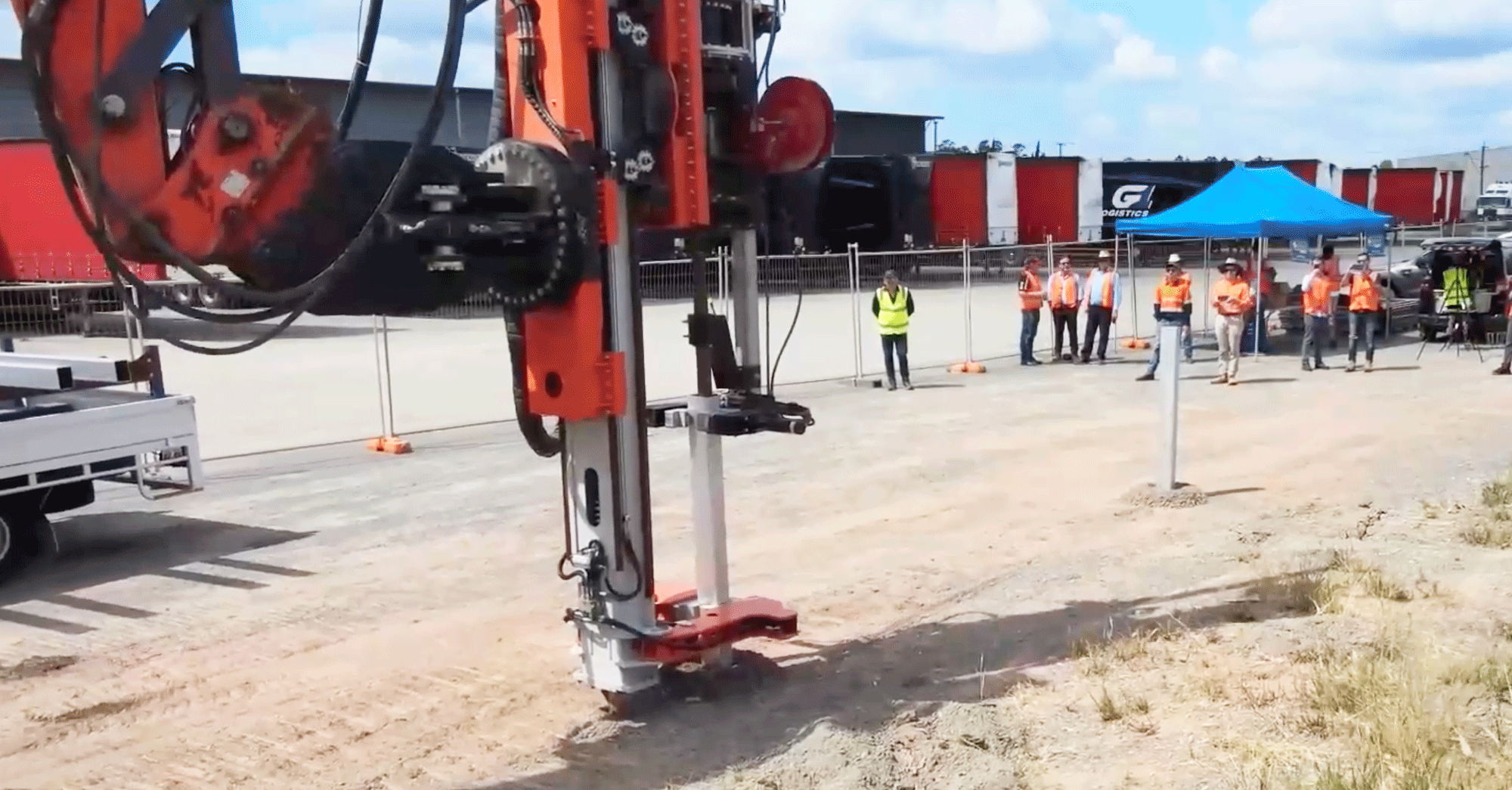

The Solar X Blade Pile is a high compression, uplift and lateral load pile that features our signature twin-blade design and bracing wings, when needed for lateral loads in very weak soils. The pile features ultra-high torque capability from an internal, bottom driven ‘screw in’ drive hub system that can penetrate the most challenging soil conditions, almost eliminating the need for pre-drilling. It has been developed and refined since 2015, and is now available to the market with our automated and fully guided GNSS (Global Navigation Satellite System) mast machine.

Comprehensive Solutions

Through Innovative Design.

Twin

Blade

Design

The Solar X Blade Pile’s twin-blade design creates precise positional tolerance and incredible vertical load capacities to answer the growing problem of frost-heave forces, and highly to extremely reactive clay soil. The Pile is able to achieve high load capacities at shallow founding depths and dramatically outperforms alternative methods for reactive clay soils in both cost and ease of installation.

Strong

Lateral

Bracing

The Solar X Blade Pile’s Bracing Wings provide substantial lateral load capacities in very weak soils, and shallow founding depths. The addition of wings allows the Pile to handle extreme wind and weather events with ease. The combination of the twin-blade design and bracing wings results in a seamless, effective solution for extremely reactive clay soils and significant wind loads.

Internally

Driven

Installation

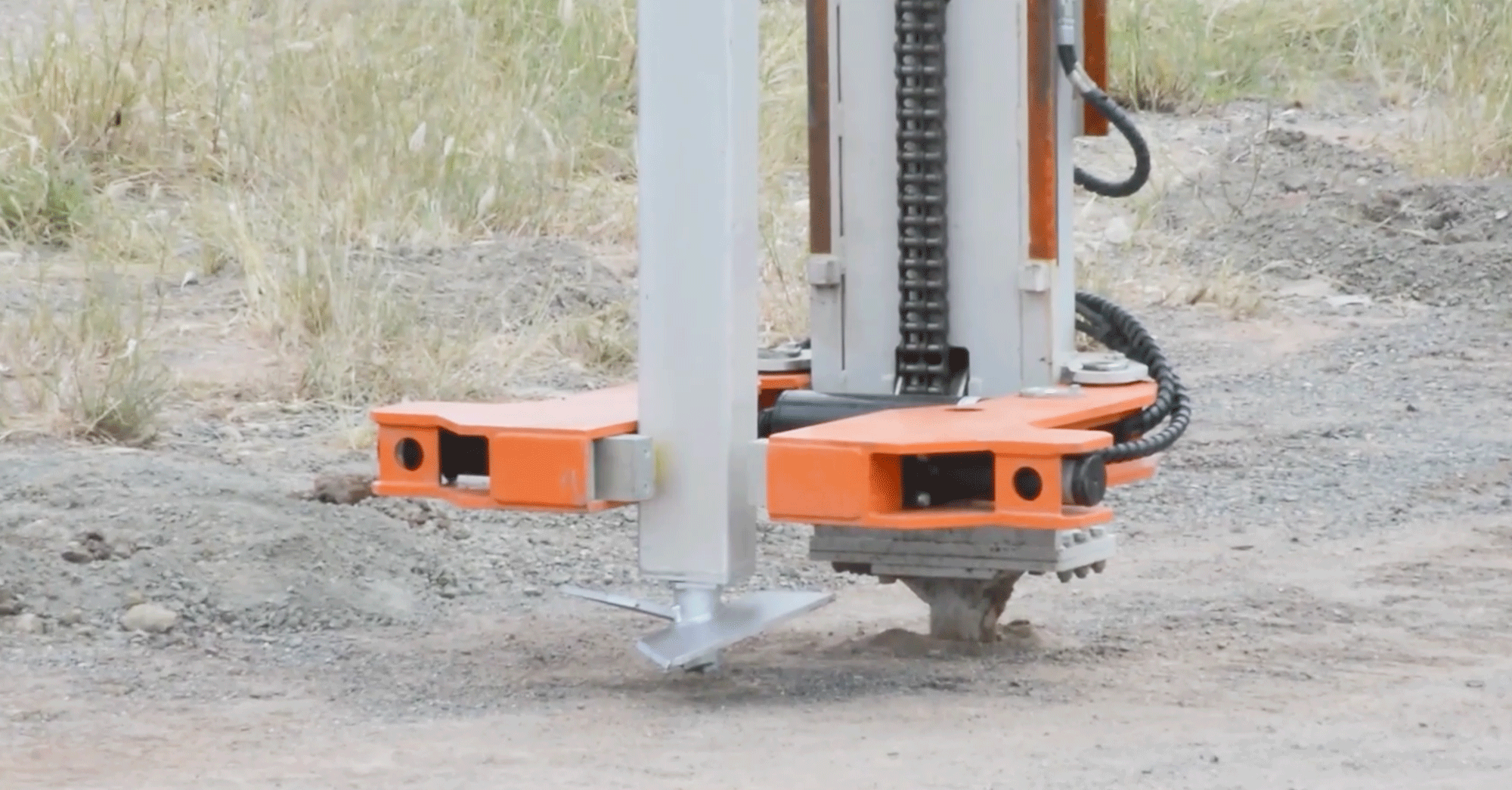

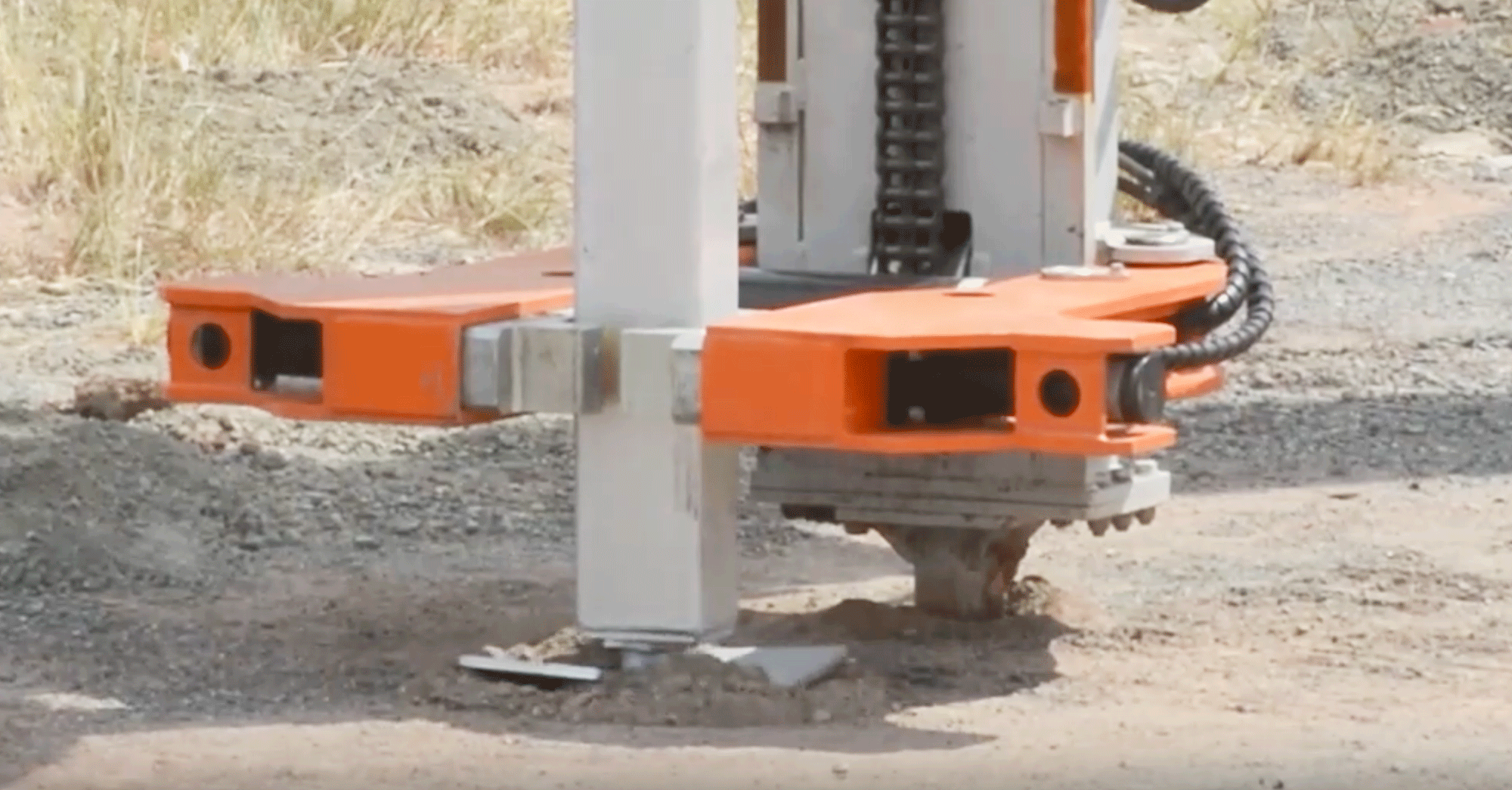

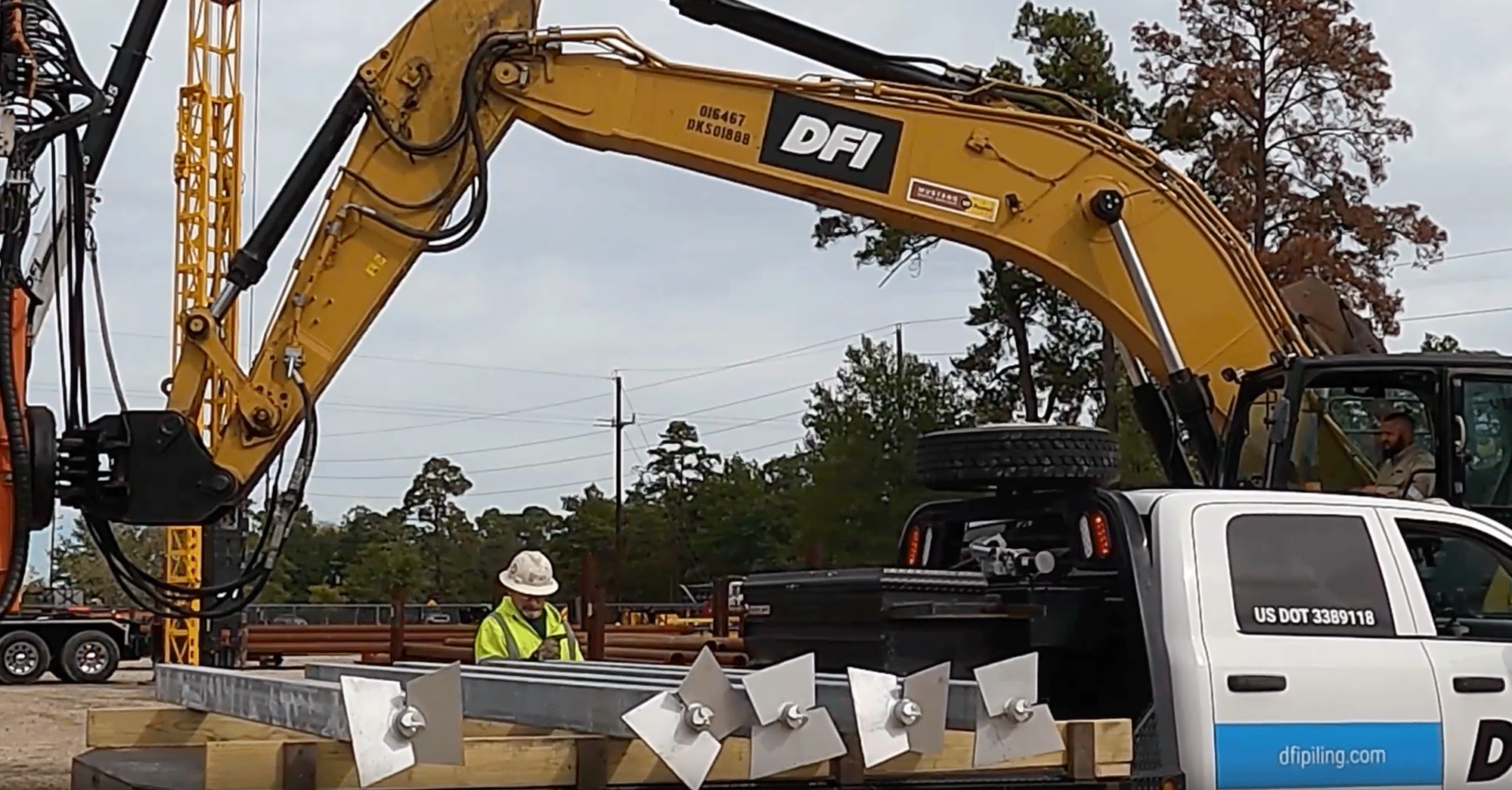

The Solar X Blade Pile is installed through an internal drive tool that fits inside the pile and connects at the base. The bottom blade section is screwed into the ground, pulling the pile down along with it. The nature of this installation system also allows the Solar X Blade Pile to be uninstalled if need be.

The rock attack drive hub system provides precise install control even through the hardest of soils and achieves a significantly higher installation torque when compared to top-driven screw piles. Photos and videos of testing can be seen in our gallery.

SXBP Features & Benefits Summary:

- Environmental Protection: 40% Average Steel Weight & CO2 Emissions Reductions

- Corrosion Issues Halved: 50% Less corrosion. Only the outside RHS surfaces are exposed

- Soft Soils: End bearing Blades combined with bracing ‘Wings’, gives high capacity at shallow depths

- Very Hard Soils: SXBP Rock attack power easily penetrates to FD, for high capacity at shallow depths

- Savings to Customer: 30% Avg Pile COST Reduction in Problem Sites. For 50% of Sites

- De-Risking Projects: Internal Bottom Drive Removes ‘Pre-Drilling’ in 90% of Problem Sites

- Screw in Piles for Solar: ’Twin Blade’ Edges Balance Pile, Unlike Helical ‘One Blade’ Edge

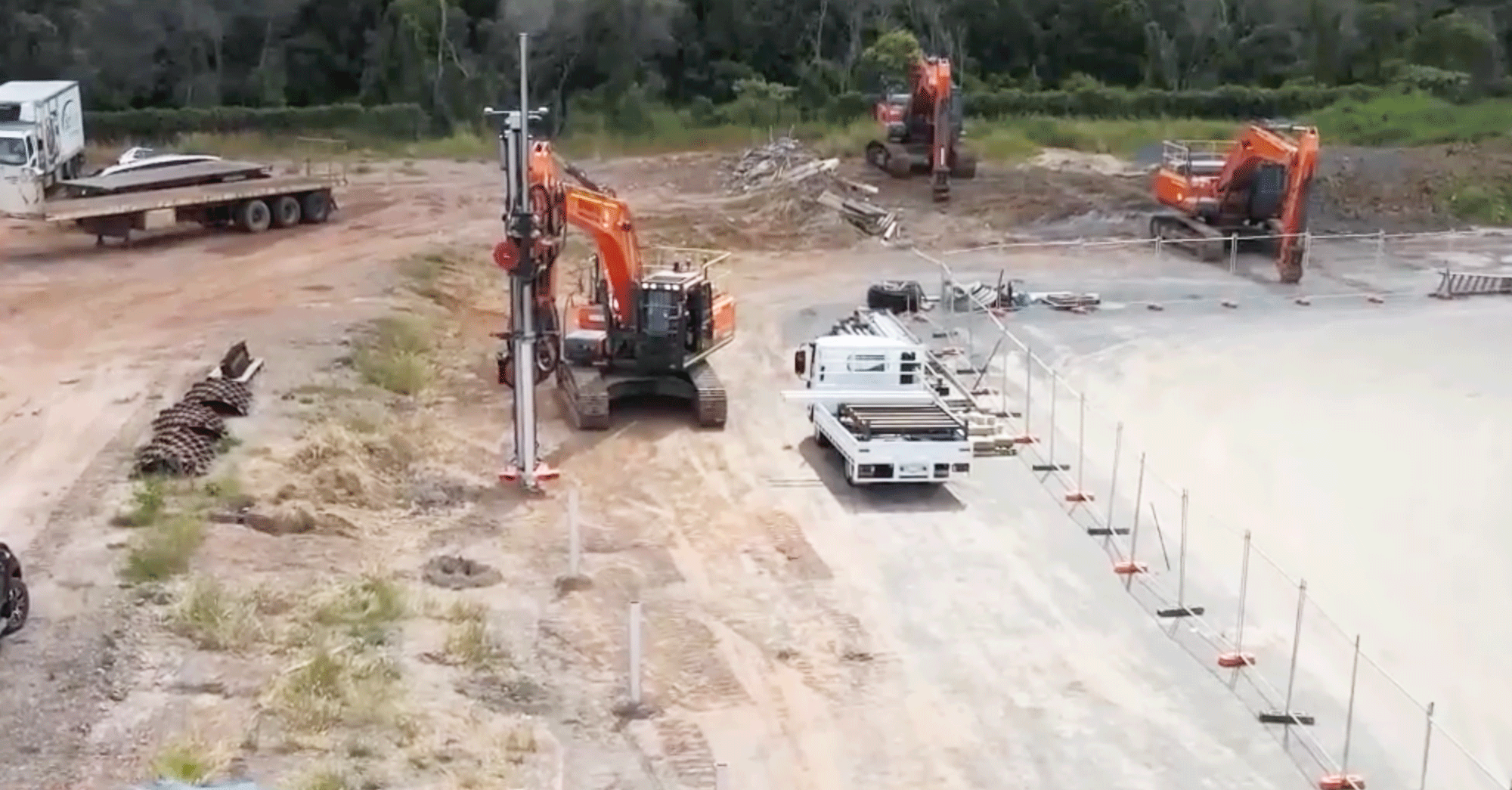

- Measurable Install Costs: Pile-to-Pile Location Install Cycle Times <3.5 Minutes

- De-Risking Projects: Cycle Times Remain <3.5 Minutes, Even in severe Problem Sites

- More Weekly Install Hours: NO Excessive Noise (Hammering) During Pile Installations

- For New Terrain Trackers: GNSS Guidance System enables Terrain Following T.O.P Heights

- Multiple Enviro & Dollar Benefits: Removable, Re-Usable & Re-Cyclable, Even Beyond Design Life

- De-Risking Market Push-Back: Ensures Uncontaminated Future Re-Use of Farming Land

- Total Ground & Tracker Control: An Optimized Geotechnical Extension of the Tracker System

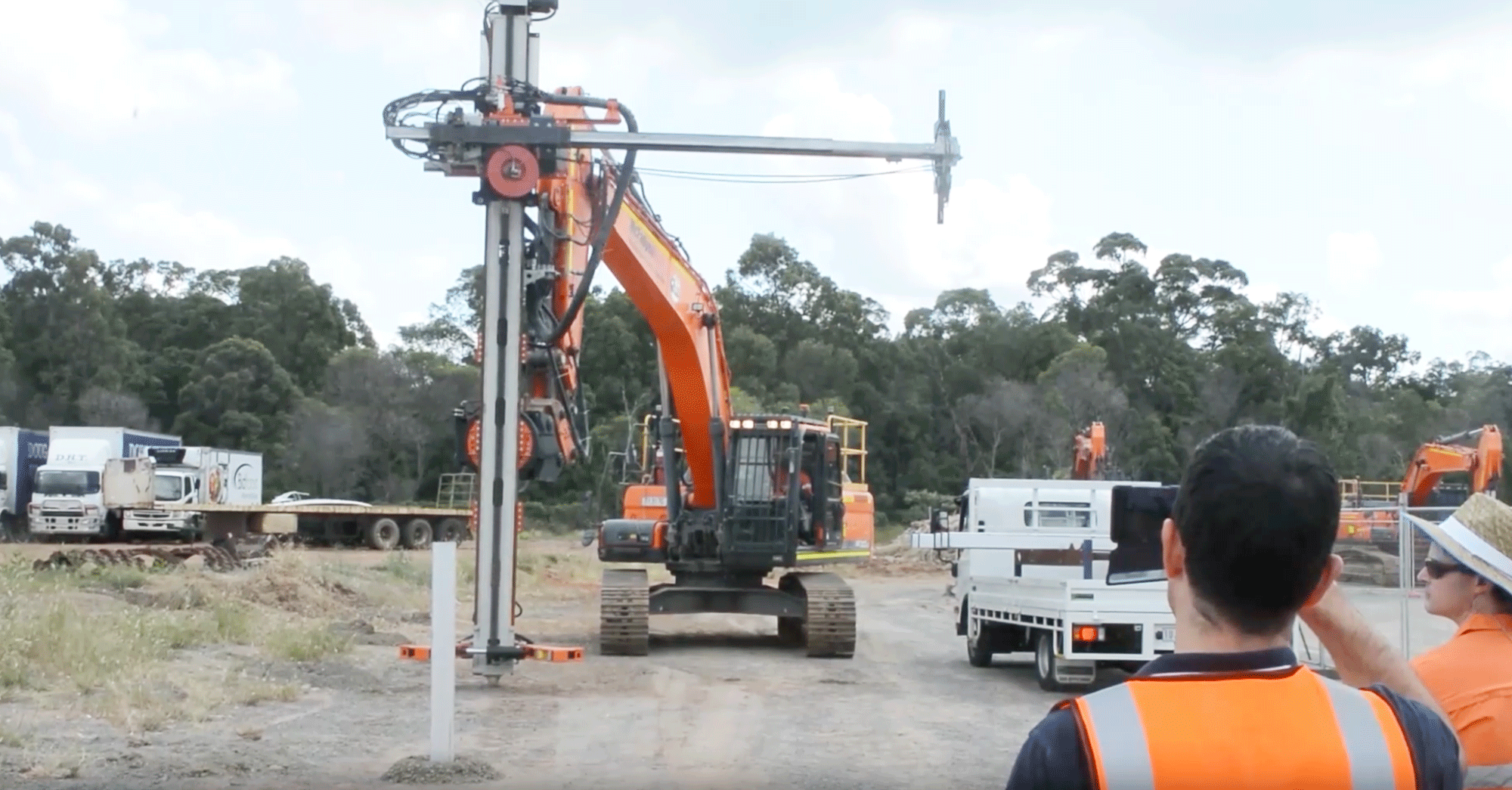

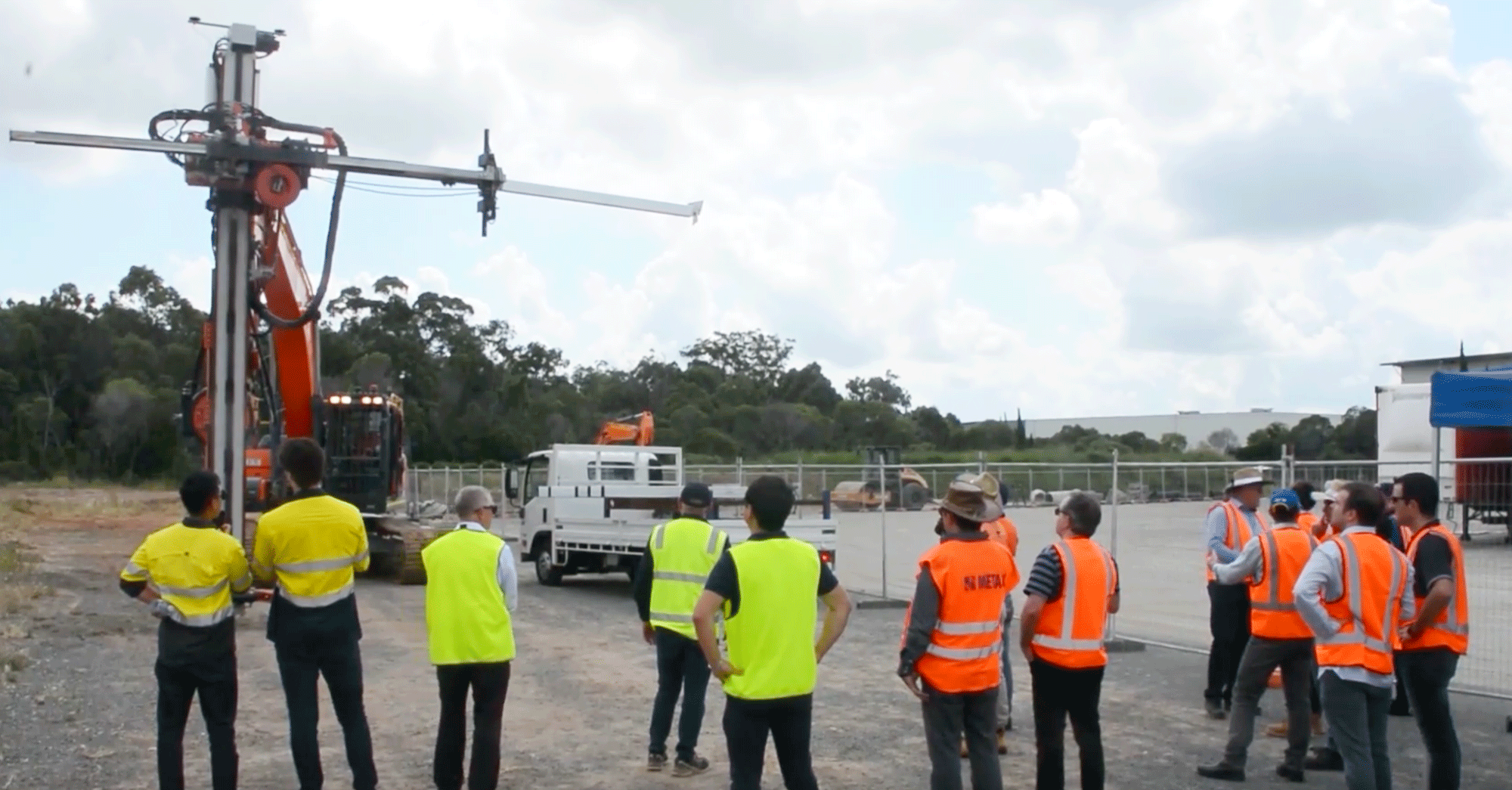

Installation Demonstration

Solar X Blade Pile Gallery

We’d Love to Hear from You.

Let’s get the conversation going about how SPI can support your next project requirements.